I've been working on this balance model for three weeks now. I decided that the iron-cross balance wheel wasn't practical and I hadn't been able to achieve a level of finish on it that I was satisfied with so I milled out a different and simpler one for the final product.

I spend half a day beveling the edges of the bridges and another day and a half turning out and burnishing the pivots of the balance staff.

It is important to burnish the pivots as it increases the hardness of the metal and polishes it at the same time. This decreases friction and increases wear-resistance. It does take time, and a delicate touch however if you are doing it by hand as I was.

To make the turning of the blued steel that is used to make the balance staff easier I special ordered some carbide cutters from Sumitomo electric. They have the smallest cutter radius on an index cutter that I could find at 1/256th inches--this allows for a nice fairly sharp shoulders to be machined into the piece while turning it. I also found that using the 1/64th inch cutters that I have work very well in turning the sloping transition from the tiny pivot to the rest of the staff.

The staff is 2x as large as the one in the 6497 movement but I had very little trouble in turning the part out even though the pivots are machined on the lathe down to 0.20mm then burnished down to 0.15 or so. The hardest part is keeping those tiny pivots nice and cylindrical during the burnishing process.

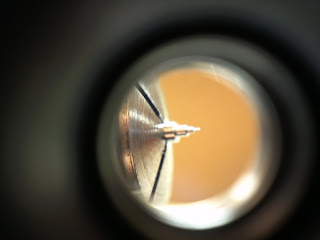

Closeup of the Jacot lathe, used for burnishing pivots

The bow is used to rotate the piece

The assembled balance wheel and bridge, just needs a final polishing

The roughly cut second balance wheel next to the original